Within the realm of heavy-duty engines, the Cummins name stands tall, synonymous with power and reliability. At the heart of Cummins engines lies the camshaft, a vital component that governs valve timing and optimizes performance. In this comprehensive article, we’ll delve into the intricacies of the Cummins engine camshaft, exploring its construction, functionality, and crucial role in driving performance.

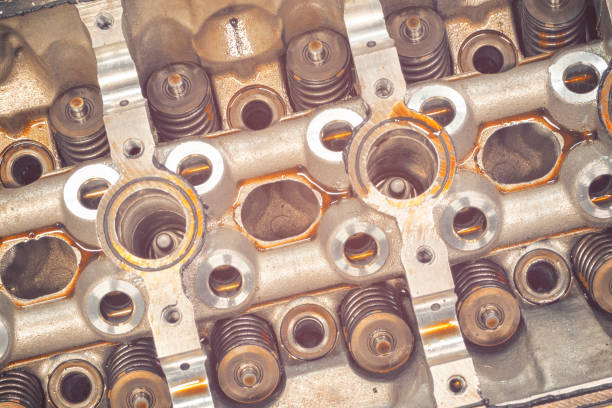

Deciphering the Components of the Cummins Engine Camshaft

The Cummins engine camshaft is a meticulously crafted assembly comprising several essential parts:

- Main Shaft: Providing structural support for the cam lobes and bearings, the main shaft ensures stability and reliability.

- Cam Lobes: These precision-machined protrusions control valve timing, optimizing air and fuel intake and exhaust gas expulsion.

- Bearings: Supporting the camshaft and facilitating smooth rotation, bearings minimize friction and wear, ensuring long-term durability.

- Timing Gear: Synchronizing camshaft rotation with the crankshaft, the timing gear ensures precise valve timing for optimal combustion.

- Sensor Targets: Enabling real-time monitoring, sensor targets assist engine management systems in monitoring camshaft position and timing for precise control.

Unveiling the Functionality of the Cummins Engine Camshaft

The Cummins engine camshaft plays a pivotal role in optimizing engine performance:

- Valve Timing Control: Dictating the timing of valve openings, the cam lobes optimize air and fuel intake and exhaust gas expulsion.

- Fuel Efficiency Enhancement: Precise valve timing maximizes fuel efficiency while maintaining power output, crucial for heavy-duty applications.

- Power Delivery Optimization: Ensuring consistent power delivery across the engine’s operating range enhances performance and drivability.

Maintaining Peak Performance

Proper maintenance is essential to preserve the performance and reliability of the Cummins engine camshaft:

- Regular Inspection: Routine checks for wear or damage on cam lobes and bearings are crucial for early issue detection.

- Lubrication: Adequate lubrication with high-quality oil minimizes friction and extends component life.

- Timely Replacement: Worn or damaged components should be promptly replaced with genuine Cummins parts to maintain optimal performance.

Conclusion: Elevating Performance with the Cummins Engine Camshaft

The Cummins engine camshaft is a masterpiece of precision engineering, serving as the backbone of power and reliability in heavy-duty applications. Its meticulous design and critical function make it an indispensable component of Cummins engines. By understanding its significance and implementing proper maintenance practices, Cummins engine owners can ensure that their machines continue to deliver optimal performance and reliability for years to come.