Manufacturing challenges are becoming more complex as products evolve and performance standards rise. Companies now need components that are not only accurate but also customized to fit highly specific applications. This is where custom machining services become essential. By delivering tailored metal and plastic parts with exact specifications, custom machining helps manufacturers solve complex design problems while maintaining quality and efficiency.

What Defines a Complex Manufacturing Project

Complex manufacturing projects often involve intricate geometries, tight tolerances, specialized materials, or low-volume production runs. Standard components rarely meet these requirements. Custom machining allows manufacturers to create parts that align precisely with engineering designs, ensuring proper fit and function. This capability is critical for industries that depend on advanced systems and specialized equipment.

The Importance of Custom Machining Services

Custom machining services enable manufacturers to move beyond limitations imposed by mass-produced components. These services support design innovation by allowing engineers to modify dimensions, materials, and finishes as needed. Precision machining also improves reliability, which is crucial when components must operate under stress, pressure, or extreme environmental conditions. The result is improved product performance and reduced risk of failure.

Material Flexibility for Specialized Needs

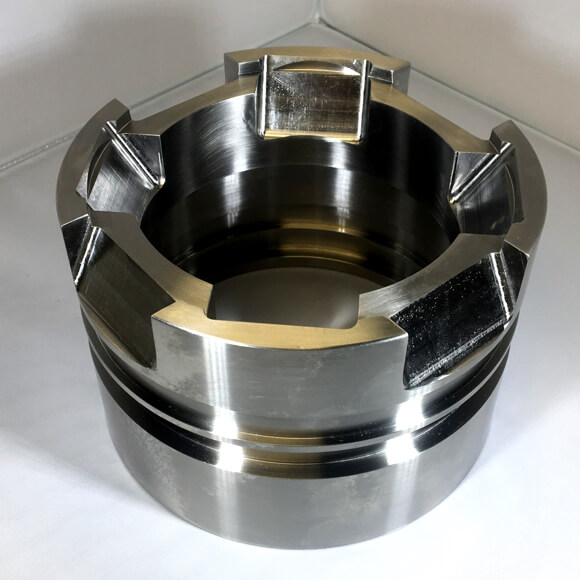

One of the main advantages of custom machining is the ability to work with a wide variety of materials. Aluminum is often chosen for its lightweight nature and corrosion resistance. Stainless steel provides strength and durability for demanding applications. Brass and copper are used for components requiring conductivity or smooth finishes. Plastics such as ABS, nylon, and PTFE are ideal for applications needing insulation, flexibility, or chemical resistance. Selecting the right material is key to achieving optimal performance in complex projects.

CNC Technology and Precision Manufacturing

Advanced CNC technology plays a major role in handling complex machining requirements. custom cnc machining enables manufacturers to produce detailed components with consistent accuracy. Computer-controlled machines follow precise programming, allowing them to create intricate shapes and maintain tight tolerances. This level of control is essential for projects that demand repeatability and precision across multiple parts.

Advantages of Custom Machining for Complex Designs

Custom machining services offer several advantages when dealing with complex designs. They provide unmatched flexibility, allowing components to be adjusted without redesigning entire systems. Precision machining reduces errors and material waste, which is especially important when working with expensive materials. Faster turnaround times also help manufacturers stay on schedule, even when projects involve multiple design iterations.

Industry Applications Requiring Complex Machining

Many industries rely on custom machining services for complex applications. Aerospace manufacturers require components that meet strict safety and performance standards. Automotive companies use custom parts for engines, transmissions, and advanced vehicle systems. Medical device manufacturers depend on precision machining for surgical instruments and implants that demand exact tolerances. Industrial and energy sectors also rely on complex machined parts designed to withstand high loads, temperatures, and pressure.

Quality Control in Complex Machining Projects

Quality control becomes even more critical when machining complex components. Reputable machine shops use advanced inspection tools to verify dimensions, tolerances, and surface finishes throughout production. Consistent inspection ensures that each part meets design specifications and performs as expected. Strong quality assurance processes help prevent costly rework and delays.

Choosing the Right Machining Partner

Selecting a machining partner with experience in complex projects is essential. Look for a provider with modern equipment, skilled technicians, and a proven track record. Effective communication and design support can make a significant difference in project success. A reliable partner will collaborate closely with clients to address challenges and deliver accurate results on time.

Cost Efficiency Through Precision Planning

Although complex machining projects may require higher upfront investment, they often lead to long-term cost savings. Precision parts reduce assembly issues, downtime, and maintenance costs. Efficient machining processes also optimize material usage and labor, improving overall cost control. For manufacturers focused on performance and reliability, custom machining services offer strong long-term value.

Custom Machining Services in Manufacturing Conversations

When teams discuss solving intricate design challenges or improving production reliability, custom machining services often come up in the conversation. Their ability to deliver precise, tailored solutions makes them a strategic asset in complex manufacturing environments.

Conclusion

Custom machining services play a crucial role in supporting complex manufacturing projects. By offering precision, material flexibility, and advanced CNC capabilities, these services help manufacturers meet demanding requirements with confidence. From initial design to final production, custom machining delivers reliable components that support innovation and long-term success.

Frequently Asked Questions

Why are custom machining services important for complex projects?

They allow manufacturers to create precise, application-specific components that standard parts cannot provide.

Can CNC machining handle intricate designs?

Yes, CNC machining is ideal for producing complex geometries with high accuracy and repeatability.

Are custom machining services suitable for low-volume production?

Custom machining services are well-suited for both low-volume and specialized production runs where precision is critical.